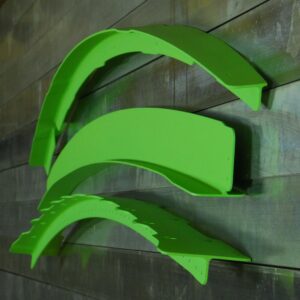

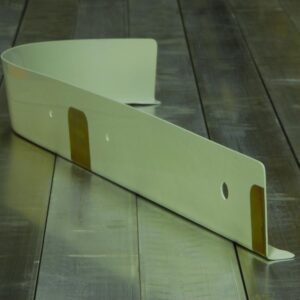

Versaform specializes in forming aerospace components from stainless steel, aluminum, and titanium. Our capabilities include manufacturing extrusions for wing boxes, structural stiffeners, and curtain tracks, as well as formed sheet stretch-formed angles and scuff plates for aircraft entryway doors. We also produce baggage hatch surrounds and seal retainers from roll-formed stainless steel and aluminum.

For helicopter MRO applications, Versaform manufactures titanium stiffeners that often feature complex lofts and twists.

Our heat treat suppliers accommodate parts up to 12 feet in length, allowing us to manage net parts up to 10 feet, and longer when the end-of-part (EOP) distance is within that limit due to preforming.

- Aluminum extrusions up to .120″ thick (6061, 6013, 7075, 2024)

- Maximum net part length: 120″

- Brake-formed and roll-formed parts in all aluminum grades

- Stainless steel and titanium up to .032–.035″ thick