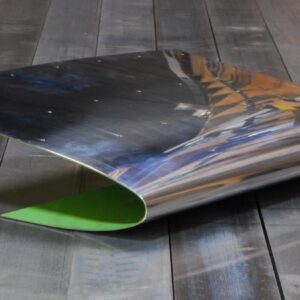

Versaform specializes in the precision manufacturing of smaller aircraft skins, with a particular focus on leading-edge components. Our team is highly experienced in producing complex geometries, including parts with significant loft, twist, and reverse contours. These capabilities enable us to deliver solutions that meet or exceed the requirements of modern aerospace applications.

One of our key strengths is the ability to form skins with reverses in the contour—an advanced technique that eliminates the need for costly and outdated drop hammer processes. By utilizing stretch forming and custom tooling, Versaform provides consistent, high-quality results with reduced labour and improved repeatability.

- Aluminum (6061, 6013, 7075, 2024) up to .100″ thick

- Annealed stainless steel up to .040″ thick